- VALVE

- 제품인증

- 거래 지역 및 고객사

- 납품실적

- 축열재

1985년 대만에서 설립된 STEMCO Group은 30년이상 가격대비 고품질의 산업용 Valve를 전세계 많은 현장에 생산 및 납품해 왔으며 2018년부터 한국 지사를 통해 영업력 증대와 적극적인 고객 대응을 통해 전세계 다양한 지역에 진출하고 있습니다.

HONEY COMB 축열재는 RTO 또는 RCO, Scrubber, 음식물쓰레기 소각장등에서 발생되는 유해가스등을 고온으로 연소시켜 유해물질을 제거하기 위한 설비에 사용되는 재료인 만큼 열팽창에 강하고 축열성 / 흡착성이 좋아야 합니다.

STEEL GATE VALVE

The gate valve can only be fully opened and fully closed to be used for cutting in the pipeline. It has such features as unlimited installation direction, small disturbed current, low pressure drop, shorter face-to-face dimension, good sealing performance and wide application range.

The most important feature of the steel gate valve of STEMCO Group is that it can be ensured that the permissible leakage rate can be lower than that specified in API6D and API600, and the middle shaft sealing can pass the USA VOC leakage test.

STEMCO Group can provide trims of various materials including materials specified by API600. We can also provide valves of various casting materials, such as carbon steel, stainless steel, alloy, Hastelloy, nickel chrome and etc.

Design standards and product range

- Design basis: ASME B16.34、GB12234、API600

- Flanged ends: ASMEB16.5、GB9113

- Butt-welding ends: ASME B16.25

- Face-to-face dimension: ASMEB16.10, GB12221

- Inspection and test: API598、API6D、JB/T9092

- Pressure rating: Class150-2500, PN16〜PN420

- Product range: 2"~36"、DN50~DN900

- Materials of main parts: WCB、LCB、WC6、WC9、C5、CF8M、Alloy20

- Trim materials: as per API600

Design features

- Certified to API600

- USA VOC middle shaft micro leakage certification

- Design of outside screw and yoke

- Bolted bonnet

- Pressure self-sealing type bonnet

- Design of wedge type flexible gate and full guide rail

- Operation methods : handwheel, bevel gear or electric operation

- Overlay welding by hard alloy can be performed on the seat surface according to specifications in API600

- Replaceable valve seat and back seat

- Integral seat and back seat are adopted in stainless steel valves

STEEL GLOBE VALVE

The stem axis of the globe valve is vertical to the sealing surface of the seat. The stem has a relatively shorter opening or closing travel with very reliable cutting operation, so that this kind of valve is very suitable for cutting and regulating medium as well as throttling.

The most important feature of the steel globe valve of STEMCO Group is the design of conical surface of the valve disc and full guide rail, and the middle shaft sealing can pass the USA VOC leakage test. STEMCO Group can provide trims and shells of various materials for the globe valve in the same way as for the gate valve.

Design standards and product range

- Design basis : ASME B 16.34, GB12235

- Flanged ends : ASME B16.5, GB9113

- Butt-welding ends : ASME B16.25

- Face-to-face dimension : ASME B16.10, GB12221

- Inspection and test : API598, API6D, JBAT9092

- Pressure rating : Class 150-2500, PN16〜PN420

- Product range : 2"~24", DN50~DN600

- Materials of main parts : WCB, LCB, WC 6, WC9, C5, CF8M, Alloy20

- Trim materials : as per API600

Design features

- USA VOC middle shaft micro leakage certification

- Conical surface of valve disc and full guide rail device

- Design of outside screw and yoke

- Bolted bonnet

- Pressure self-sealing type bonnet

- Lift type stem and handwheel

- Operation methods : handwheel, bevel gear or electric operation

- Overlay welding by hard alloy can be performed on the seat surface according to specifications in API600

- Replaceable valve seat and back seat

- Integral seat and back seat are adopted in stainless steel valves

STEEL CHECK VALVE

The check valve indicates a kind of valve in which the valve disc is automatically opened by the pressure produced by the flowing of the medium itself, and closed by the reverse pressure or the weight of the valve disc, so as to make the fluid flow toward one direction.

The check valves include different types such as swing type, lift type and tilting disc type. Designed in accordance with specifications In API6D, the full-open type check valves of STEMCO Group are applied in transportation lines for crude oil and natural gas.

Design standards and product range

- Design basis : ASME B 16.34, GB12236, API6

- Flanged ends : ASME B16.5, GB9113

- Butt-welding ends : ASME B16.25

- Face-to-face dimension : ASME B16.10, GB 12221

- Inspection and test : API598, API6D, JB/T9092

- Pressure rating : Class150-2500, PN16~PN420

- Product range : 2"〜36" DN50~DN900

- Materials of main parts : WCB, LCB, WC6, Wc9, C5, CF8M, Alloy20

- Trim materials : as per API600

Design features

- Swing type valve disc

- Tilting disc type valve disc

- Bolted bonnet

- Pressure self-sealing type bonnet

- Suitable for horizontal and vertical installation

- Flanged ends

- Butt-welding ends

- Pressure self-sealing type bonnet

- Overlay welding by hard alloy can be performed on the seat surface according to specifications in API600

- Replaceable valve seat

- Integral seat and back seat are adopted in stainless steel valves

- The built-in structure is adopted for connecting the pin and valve disc, so there is no external leakage point

FORGED STEEL VALVE

The forged steel valve is generally used for the high pressure valve. These valves include forged steel gate valves, globe valves and check valves in accordance with American standard and national standard.

The valves of this kind produced by STEMCO Group have multiple varieties and diversified specifications ranging from 1/2" to 3' which can meet customer's technical demands and delivery requirement.

STEMCO Group can provide trims and shells of various materials according to specifications in API602.

Design standards and product range

- Design basis : API602, BS5352, ASME B16.34

- Socket welding ends : ASME B16.11, DIN3202

- Threaded ends : ASME B1.20.1

- Butt-welding ends : ASME B16.25

- Face-to-face dimension : ASME B16.10, GB12221

- Inspection and test : API598, API6D, JB/T9092

- Pressure rating : Class600〜2500, PN100〜PN420

- Product range : 1/2"~3", DN15-DN80

- Materials of main parts : A105, F11, F22, F5, F316

- Trim materials : as per API600

Design features

- Bolted bonnet

- Welded bonnet

- Pressure self-sealing type bonnet

- Screwed ends

- Socket welding ends

- Design of outside screw and yoke for gate valves and globe valves

- Lift type valve disc (spring can be added) for check valves

- Swing type valve disc is also available for check valves

- Overlay welding by hard alloy can be performed on the seat surface according to specifications in API602

- Body seat is adopted in stainless steel valves

- Bellows seal can be made according to requirements

POWER PLANT VALVE

Compared with other valve products, the power plant valve has Its feature that It is used in high temperature and high pressure circumstance and some parts are of welding type. Its performance and technical features and special working conditions endow the product with characteristics that can't be replaced by other products.

The power plant valve of STEMCO Group adopts mold forged, casting or precise CNC machining. It can provide absolutely reliable pressure with sealed bonnet. And it is guaranteed that the seat leakage is lower than the standard leakage. It passed the USA VOC middle shaft leakage test. If it Is cast, the important parts of shell and butt-welding ends are subjected to radiation test according to specifications in ASME B 16.34

For the power plant valve of STEMCO Group, the body materials include carbon steel and Cr-Mo-V Steel. Overlay welding by cobalt-base alloy is performed on the sealing surface. The stem surface adopts anticorrosive nitriding protection or chemical nickel plating protection.

Design standards and product range

- Design basis : ASME B 16.34, API600, DLT 531-1994, JBT3595-2002

- Socket welding ends : ASME B16.11, DIN3202

- Butt-welding ends : ASME B16.25

- Face-to-face dimension : ASME B16.10, GB12221

- Inspection and test : API598, API6D, JB/T9092

- Pressure rating : Class600〜2500, PN100~PN420

- Product range : 1/2"~24", DN15-DN600

- Materials of main parts : WCB, WC6, WC9, C5, C12, Alloy20

Design features

- Bolted bonnet (below PN100)

- Pressure self-sealing type bonnet (above PN100)

- Butt-welding ends

- Socket welding ends (below 2")

- Design of outside screw and yoke for gate valves and globe valves

- Swing type valve disc or tilting disc type valve disc for check valves

- Overlay welding by cobalt-base alloy is performed on the sealing surface

- The stem surface adopts anticorrosive nitriding protection or chemical nickel plating protection

- Butt-welding ends 100% RT

- Important parts of shell 100% RT

SIDE ENTRY BALL VALVE

The floating ball side entry ball valve is a kind of commonly used valve. It is named due to the fact that the ball and stem pass through the axis of flow channel The side entry ball valves of STEMCO Group include low platform type and high platform type.

The low platform type products are suitable for manual operation and electric or pneumatic actuator can also be additionally installed if necessary. For the high platform type products, the electric or pneumatic actuator can be installed without extra yoke.

Design standards and product range

- Design basis : ASME B16.34/API608/DIN3357 En12516 GB/T1224 GB/T12237

- Face-to-face dimension : ASME B16.1Q/DIN3202/GB/T12221

- Flanged ends : ASME B16.5/DIN2501/GB/T9113.1

- Butt-welding ends : ASME B 16.25/

- Socket welding ends : ASME B16.11/

- Wall thickness : ASME B16.34/EN12516

- Fireproof test : API607 18010479

- Inspection and test : API6D/API598/EN12266/GB/T13927

- Product range : 1/2"~8", DN15~DN200

- Materials of main parts : WCB, CF8, CF8M, WC6, WC9

- Seat materials : PTFE, RTFE or metal hard seal

Design features

- Design of fireproof structure and obtaining the certification

- IS05211 platform design is adopted for the convenience of installing the actuator

- Antistatic design between stem, body and ball

- Anti-blow-out stem design

- The pressure balancing hole is provided on the steel ball

- The low platform products adopt packing gland type middle shaft

- The double-layer stem packing and double butterfly spring structure of the high platform products play a self-compensation function for the middle shaft seal

- The body is provided with a device for cleaning the valve cavity

- According to the structural forms, the valves include one-piece type, two-piece type and three-piece type flanged ball valves, wafer flanged ball valves, and some butt-welding and socket welding ball valves

TOP ENTRY BALL VALVE

The floating ball top entry ball valve of STEMCO Group is a kind of ball valve whose trims can be replaced and maintenance can be made on the pipeline. The creativity comes from the gate valves and globe valves. The ball and seat are installed through the middle flange vertical to the axis of flow channel. The top entry ball valves of STEMCO Group include low platform type and high platform type.

The low platform type products are suitable for manual operation and electric or pneumatic actuator can also be additionally installed if necessary. For the high platform type products, the electric or pneumatic actuator can be installed without extra yoke.

Design standards and product range

- Design basis : ASME B16.34/API608

- Face-to-face dimension : ASME B16.10

- Flanged ends : ASME B16.5

- Butt-welding ends : ASME B16.25/

- Socket welding ends : ASME B16.11/

- Wall thickness : ASME B16.34

- Fireproof test : API607

- Inspection and test : API6D/API598

- Product range : 1/2"~8", DN15-DN200

- Materials of main parts : WCB,CF8,CF8M,WC6,WC9

Design features

- IS05211 platform design is adopted for the convenience of installing the actuator

- Antistatic design between stem, body and ball

- Anti-blow-out stem design

- The pressure balancing hole is provided on the steel ball

- The low platform products adopt packing gland type middle shaft

- The double-layer stem packing and double butterfly spring structure of the high platform products play a self-compensation function for the middle shaft seal

- The body is provided with a device for cleaning the valve cavity

- According to the structural forms, the valves include butt-welding type, socket welding type, flanged type and screwed type

- Seat and steel ball can be replaced on the pipeline

- Ball taper design

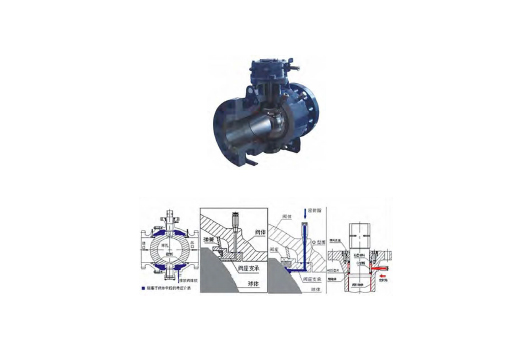

TRUNNION BALL VALVE

The trunnion ball valve is used for cutting or connecting the medium in various pipelines of Class 150 ~ Class 1500 and PN 16 ~PN 100 . It can be suitable for various media such as water , steam , oil , liquefied gas . natural gas , coal gas , nitric acid , acetic acid , oxidizing media , urea and etc . It is widely used in such industries as chemical industry , petroleum , natural gas , metallurgy and etc . The driving modes of the trunnion ball valve include worm and worm gear driving , manual driving , pneumatic driving and electric driving . The trunnion ball valves generally adopt flange connection , and butt-welding connection is also adopted. The seat can be soft seal seat or metal hard seal seat.

Design standards and product range

- Design basis and product range : API6D/API608/GB/T12237

- Face-to-face dimension : ASME B16.10/GB/T12221

- Flanged ends : API605/ASME B16.47/GB/T9113

- Butt-welding ends : ASME B16.25/GB/T12224

- Wall thickness : ASME B16.34

- Fireproof test : API607

- Inspection and test : API6D/API598 JB/T9092

- Product range : 6"~24", DN150~DN600

- Materials of main parts : WCB, LCB.WC6, WC9,CF8,CF8M

- Seat materials : PTFE, RTFE or metal hard seal

Design features

- IS05211 platform design is adopted for the convenience of installing the actuator

- Double block and bleed function

- Anti-blow-out stem design

- The pressure balancing hole is provided on the steel ball

- The body is provided with a device for cleaning the valve cavity

- Automatic pressure relief function

- Fireproof and antistatic design

- Sealant injection system for emergency seal

- Multiple driving modes facilitate the realization of automatic control

- Reliable stem seal and low operating torque. Metal hard seal seat can be made according to requirements.

INSIDE THREAD BALL VALVE

The inside thread ball valves are mainly below 3" ranging from 1000WOG to 2000WOG. The widely used small diameter floating ball soft seal ball valves select shells and seats of different materials, suitable for various media such as water, steam, oil, liquefied gas, natural gas. coal gas. nitric acid, acetic acid, oxidizing media, urea and etc. They are widely used in such industries as chemical industry, petroleum, natural gas. metallurgy and etc, The inside thread ball valves are mainly below 3", because it is not suitable to make threads for bigger sizes.

Design standards and product range

- Design basis and product range : ASME B 16.34/API608

- Threaded ends : ASME B1.20.1/BS21/DIN2999/159IS0228/1 JISB0203

- Wall thickness : ASME B16.34/EN12516-3

- Inspection and test : API6D/API598/EN12266

- Product range : 1/2"~4", DN15-DN100

- Materials of main parts : WCB, LCB, WC6, WC9, CF8, CF8M

- Seat materials : PTFE, RTFE, PEEK, EKONOL, NYLON and etc.

Design features

- Anti- blow- out stem design

- The pressure balancing hole is provided on the steel ball

- Full bore or reduced bore

- Various threaded ends are optional

- Fireproof and antistatic design

- Compact structure

- Spiral spring is available. TA-LUFT micro leakage design

BUTTERFLY VALVE

The butterfly valve is a kind of valve that adopts the round butterfly board as the disc and opens, closes and regulates the flow channel through the rotation of stem. The butterfly board of the butterfly valve is installed at the diameter direction of the pipe. The butterfly valve has such features as simple structure, economic material consumption, small volume and light weight With small installation dimensions, low driving torque, convenient and rapid operation, rapid opening and closing can be realized just through a rotation of 90° In addition, It has good flow regulating function and closed sealing performance. In the fields for large A middle sizes and low & middle pressure, the butterfly valve is a leading valve form. STEMCO Group has developed series of central line butterfly valves, double-eccentric butterfly valves and three-eccentric butterfly valves with complete varieties and specifications ranging from 2" to 80" for customers to select. The body materials of the butterfly valves of STEMCO Group include carbon steel and ductile iron. The sealing surface can be PTFE , EPDM, NBR soft seals or metal seal.

Design standards and product range

- Design basis : API609, JBT3595-2002

- Socket welding ends : ASME B16.11

- Threaded ends : ASME B1.20.1

- Butt-welding ends : ASME B16.25

- Face-to-face dimension : ASME B16.10, GB12221

- Inspection and test : API598, API6D, JB/T9092

- Pressure rating : Class 150-600, PN16~PN40

- Product range : 2"~80", DN50-DN2000

- Materials of main parts : WCB, CF8, CF8M and etc.

Design features

- Streamlined water face and water discharging surface of butterfly board

- Flange type

- Wafer type or lug type

- The stem bush adopts self-lubricating material

- Right angle rotation and abrasion-free design for the three-eccentric butterfly valve

- The metal seal butterfly valve with integral hard surface valve seat is featured by long service life and little maintenance

- The full metal structure and zero leakage performance make the valve featured by "intrinsic fireproof safety"

- The valve indicator makes it convenient to view the position of the butterfly board

AUTOMATION VALVE

The automation valve fs additionally installed with pneumatic or electric actuator on the basis of the manual valve. The automation valve Is provided with automatic control features required in the current industries, such as remote control. The automation valves of STEMCO Group include three-piece screwed type and flanged type and two-piece flanged type ball valves, as well as wafer type, lug type or flanged type butterfly valves and other valves in accordance with American standard, national standard and German standard.

Design standards and product range

- Design basis and product range: API6D/API608/API609/GBT12237/JBT3595

- Face-to-face dimension: ASME B16.10/GB/T12221

- Flanged ends: API605/ASME B16.47/GB/T9113

- Butt-welding ends: ASME B16.25/GB/T12224

- Socket welding ends: ASME B16.11

- Threaded ends: ASME B1.20.1

- Wall thickness: ASME B16.34

- Fireproof test: API607

- Inspection and test: API6D/API598 JB/T9092

- Materials of main parts:WCB,CF8, CF8M and etc.

Design features

- IS05211 middle platform is adopted for the convenience of installing the actuator

- Manual operation is available when the valve actuator is abnormal

- For the high platform type ball valves, the actuator can be installed without extra yoke

- Limit switch is optional according to customer requirements

- Limiting stopper is optional according to customer requirements

- Valve indicator is optional according to customer requirements

- Explosion-proof grade is optional for electric valves according to customer equirements

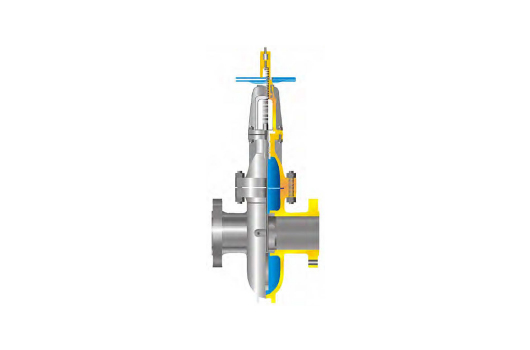

CONTROL VALVE

After design improvement was made on the basis of the traditional control valve, the performance of the control valve has been greatly enhanced. The products include pneumatic type, electronic & electric type, intelligent electric type single seat and cage type valves and ball valves, The flow characteristics include linear, equal percentage and rapid opening type.

Design standards and product range

- The leakage meets the requirements in ANSI B16.1041V.

- Flanged ends : ASME B16.5/GB/T9113

- Butt-welding ends : ASME B16.25

- Socket welding ends : ASME B16.11

- Pressure rating : Class 150-1500, PN16-250

- Product range : 1/2"~8", DN15~DN200

- Materials of main parts : WCB, CF8, CF8M, Alloy20

Design features

- The valve body adopts S model streamlined flow channel design with low pressure loss and high flow

- The upper guide type design in the valve spool with the guide cover being inserted into the bonnet can reduce leakage points.

- The nearly ideal spool profile design makes the flow characteristic curve have higher precision and wider adjustable range.

- The valve spool has wide guiding area and good shock resistant performance.

- Multi-spring pneumatic actuator and electric actuator

- Provided with linear, equal percentage and rapid opening type flow characteristics.

- Soft and hard seal seats are optional

- Air to open and air to close are optional

THROUGH-CONDUIT GATE VALVE

The flat gate valves include single flat gate valves and double flat gate valves. With double block and bleed function, they are used in transportation pipelines for petroleum, natural gas and etc. STEMCO Group can provide straight-through flat gate valves complying with API6D design. The materials for shells and trims of valves can be provided according to API6D requirements, such as carbon steel, stainless steel, alloy steel and etc,

Design standards and product range

- Design basis : API6D, ASME B 16.34, JB/T5298

- Flanged ends : ASME B16.5, GB/T9113

- Butt-welding ends : ASME B16.25, GB/T12224

- Face-to-face dimension : ASME B16.10fGB/T12221

- Inspection and test : API598, API6D, JB/T9092

- Pressure rating : Class 150-600, PN16~PN100

- Product range : 4"~36", DN100~DN900

- Materials of main parts : carbon steel, stainless steel

- Trim materials : PTFE, RTFE soft seals and hard seal

Design features

- Certified to API6D

- USA VOC micro leakage certification

- Designs of single flat gate and double flat gate are optional

- Double block and bleed function

- Operation methods: handwheel, bevel gear or electric operation

- The seat can be PTFE soft seal or metal- to- metal hard seal

- Design of emergency sealant injection structure

BELLOW SEALED VALVE

The bellows valve is often used in locations where the sealing performance of the stem is severely required without any external leakage permitted . The bellows valves of STEMCO Group include bellows gate valves , bellows globe valves and bellows ball valves . The bellows valve can enhance the sealing performance at the stem part eliminate the looseness and leakage caused by rotation movement of the stem and protect the stem from being corroded by the medium and endow the stem with the feature of dual packing sealing. It is suitable for such industries as polyester, chemical fiber, heat medium pipe, high vacuum and nuclear industry

Design standards and product range

- Design basis : API600, API602, API6D, ASME, B 16.34, GB/T12234

- Flanged ends : ASME B16.5, GB/T9113

- Butt-welding ends : ASME B16.25, GB/T12224

- Face-to-face dimension : ASME B16.10, GB/T12221

- Inspection and test : API598, API6D, JB/T9092

- Pressure rating : Class 150〜1500, PN16~PN250

- Product range : 1/2"~24", DN15-DN600

- Shell materials : WCB, CF8M, WC6, WC9

- Bellows materials : 316. Inconel, Hastelloy C

Design features

- Formed bellows

- No fault and leakage under operations of 10,000 times

- Design of bellows and packing dual stem seal

- Overlay welding by hard alloy can be performed on the seat surface according to specifications in API600

- Guaranteeing zero leakage of stem

CRYOGENIC VALVE

The cryogenic valve is a kind of valve used under the conditions with temperature below -196℃. The products include cryogenic ball valves, gate valves, globe valves and cryogenic check valves. The cryogenic treatment and prolonged stem design are adopted to ensure the performance. They are suitable for liquefied natural gas, liquefied gas, petroleum gas and etc.

Design standards and product range

- Product varieties : gate valves, globe valves, ball valves, butterfly valves and check valves

- Design basis : API600, API6D, JB/T7749

- Flanged ends : ASME B16.5, GB/T9113

- Butt-welding ends : ASME B16.25, GB/T12224

- Face-to-face dimension : ASME B16.10, GB/T12221

- Inspection and test : API598, API6D, JB/T9092

- Cryogenic inspection and test : JB/T7749

- Pressure rating : Class 150-600, PN16-PN100

- Product range : 1/2"~24" DN15-DN600

- Shell materials : CF8, CF8M

Design features

- Design of safe prolonged stem

- Design of bleeding in case of abnormal pressure increase in middle cavity

- Design of prolonged bonnet for gate valves and globe valves

- Antistatic design for ball valves

- Operation methods : manual, electric or pneumatic operation

- Overlay welding by hard alloy can be performed on the seat surface according to specifications in API in 600

- The stem length can be made according to users' requirements.