- VALVE

- 产品认证

- 交易区域 及客户

- 供应业绩

- 储热材

STEMCO Group于1985年在台湾成立,过去30多年来一直生产和交付高品质的工业阀门。自2018年以来,我们扩大了销售能力,并通过我们在韩国的分公司积极响应客户。

HONEY COMB储热材料是一种用于在设施中通过高温燃烧RTO或RCO,洗涤塔,食物垃圾焚烧炉等高温气体来去除有害物质的材料,应具有较强的热膨胀性和良好的储热/吸附性。

HONEY COMB储热材

我们的产品的比热容超过1000 J / kgk,最高工作温度超过1700°C。它们用于再加热,炉子(如烤炉)的蓄热,均热炉和裂化炉。

它可以节省40%以上的燃料,产量提高15%以上,并且排放的烟气温度低于150°C。该产品可有效用于RTO和RCO工厂的气体净化处理阶段,工业炉的热交换和储热过程,或用于气体和粉尘收集和净化的过滤和净化装置/包装塔设备。与常规产品相比,该产品对降低系统能耗具有很大的影响。 所有产品和材料均根据个别客户的需求和规格制造。

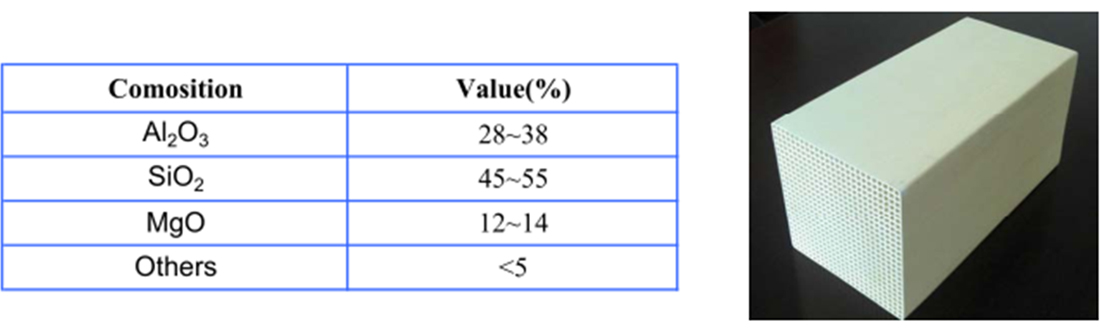

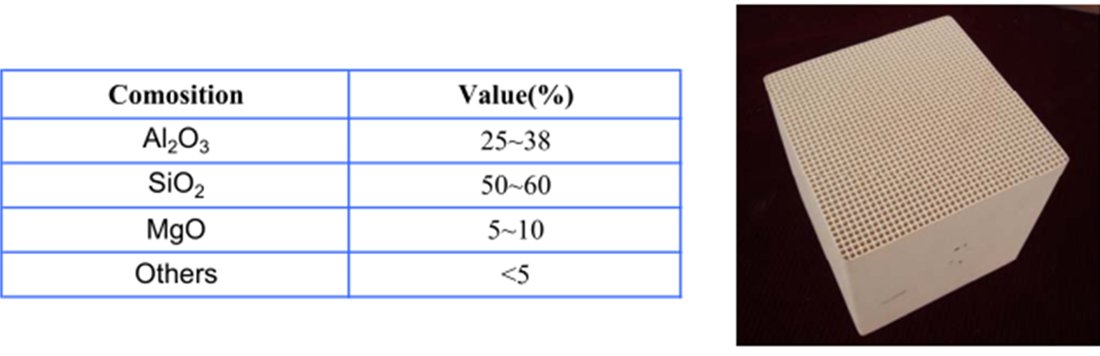

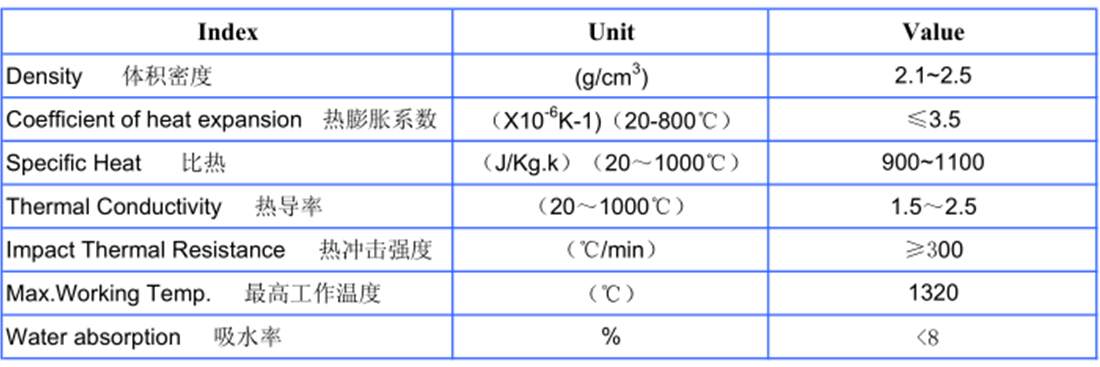

HONEY COMB储热材的材料

Alumina Ceramics

Alumina Ceramics is the most widely used advanced ceramic material. Owing to its highly strong ionic inter-atomic bonding, alumina offers good performance in terms of chemical and thermal stability, relatively good strength, thermal and electrical insulation characteristics at a reasonable price. With a range of purities and also the relatively low cost in raw material production it is possible to utilize alumina for wide ranging applications across a variety of different industries.

Silicon Carbide Ceramics

Silicon carbide is notable for its hardness, high melting-point and high thermal conductivity. It can retains its strength at temperature as high as 1400 °C and offers excellent wear resistance and thermal shock resistance. It has well-established and wide-spread industrial applications as catalyst supports and hot-gas or molten metal filters because of its low thermal-expansion coefficient and good thermal-shock resistance as well as excellent mechanical and chemical stability at elevated temperature environments.

Mullite Ceramics

Mullite occurs very rarely in nature because it only forms at high temperature, low pressure conditions, so as an industrial mineral, mullite has to be supplied by synthetic alternatives. Mullite is a strong candidate material for advanced ceramics in industrial process for its favourable thermal and mechanica properties: low thermal expansion, low thermal conductivity, excellent creep resistance, suitable high temperature strength and utstanding stability under harsh chemical environments.

Cordierite Ceramics

MCordierite has a superior thermal shock resistance due to their intrinsic low coefficient of thermal expansion (CET), coupled with relatively high refractoriness and high chemical stability. Therefore, it is often used as high temperature industrial applications, such as: heat exchangers for gas turbineengines; honeycomb-shaped catalyst carriers in automobile exhaust system.

Zirconia Oxide Ceramics

Ceramics Zirconia can be an ideal material of high-strength and high-toughness when proper compositions, such as: magnesium oxide (MgO), yttrium oxide, (Y2O3), or calcium oxide (CaO), are added to control an otherwise destructive phase transformation.The micro structural features of zirconia ceramics also make it an engineering material choice of wear and corrosion resistance, damage and degradation tolerance in a wide range of applications.

Corundum Ceramic

1. high purity: Al2O3> 99%, good chemical aaresistance

2. temperature resistance, long-term use aaat 1600 °C, 1800 °C short-term

3. thermal shock resistance and good aaresistance to crack

4. slip casting, high density, high purity aaalumina

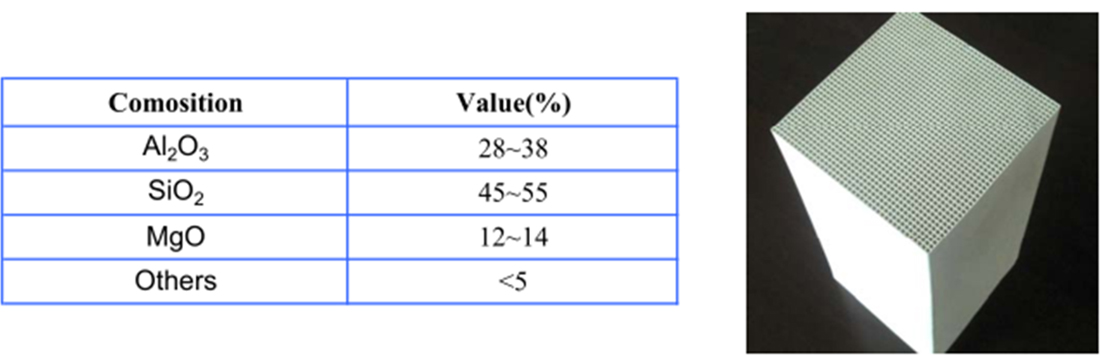

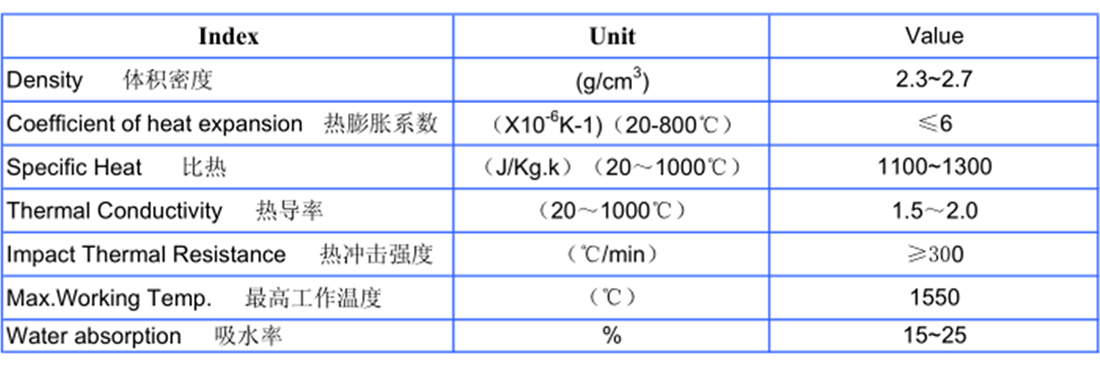

01. 多孔堇青石

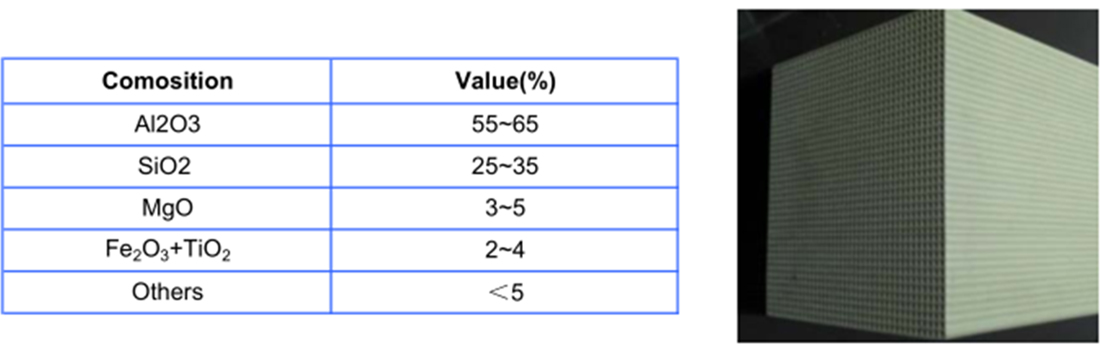

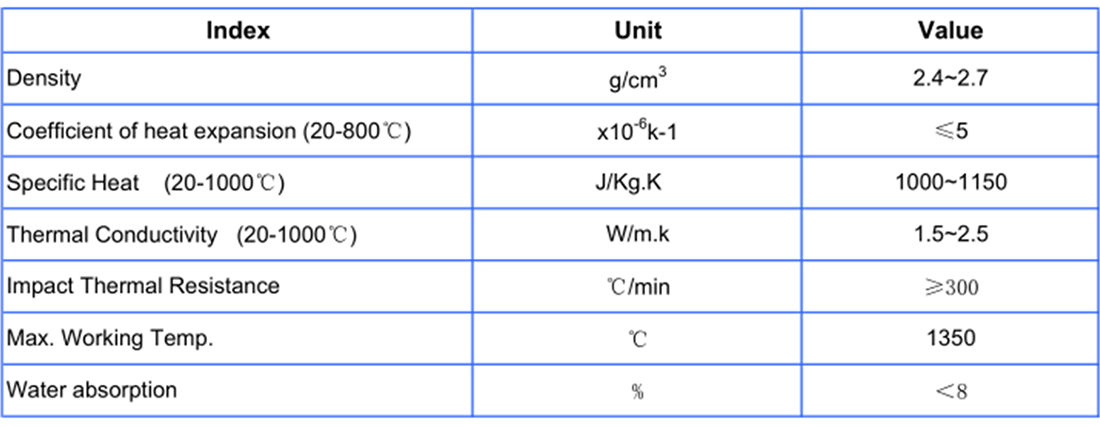

Chemical analysis

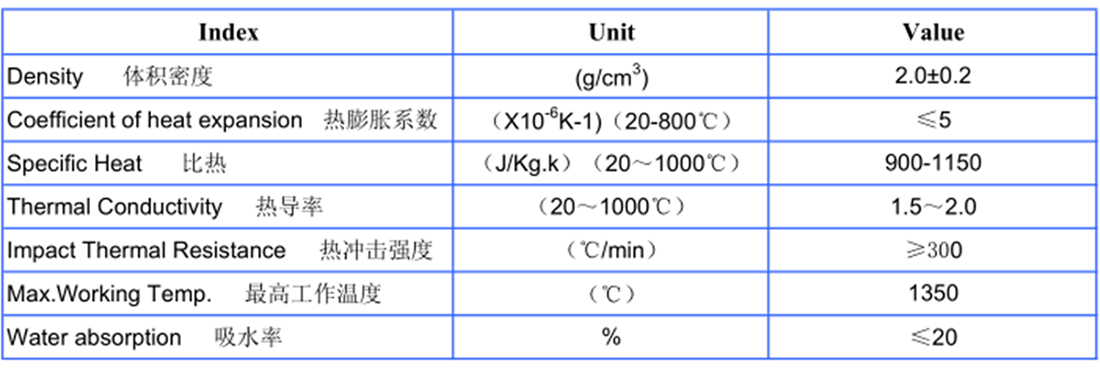

Physical properties

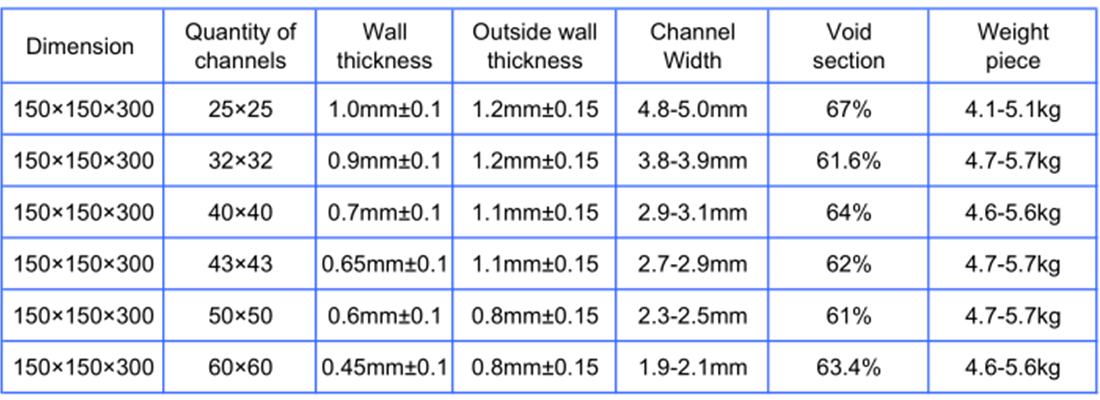

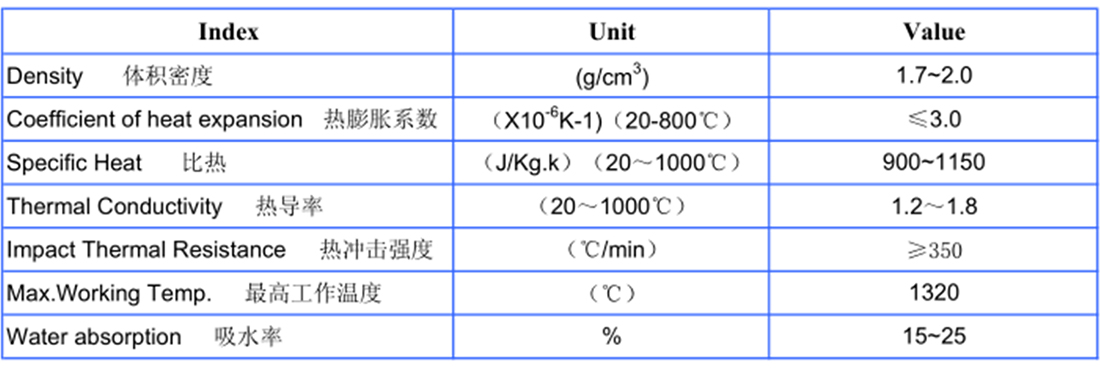

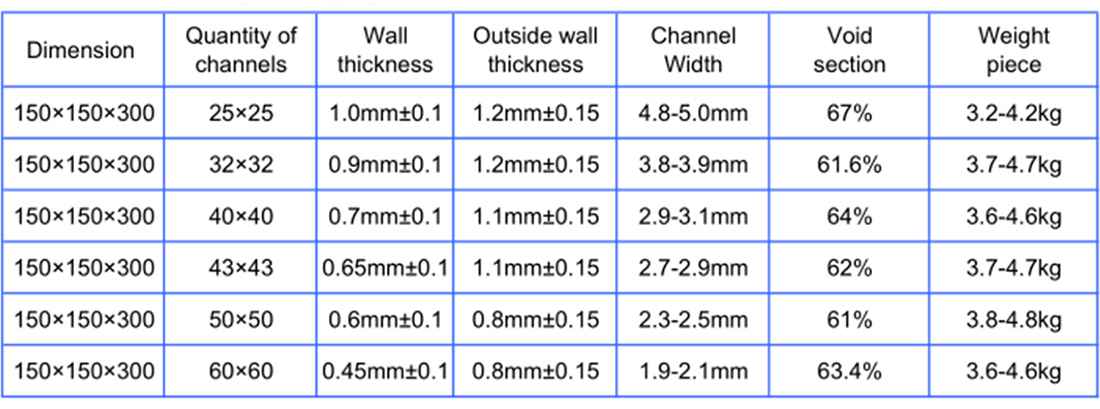

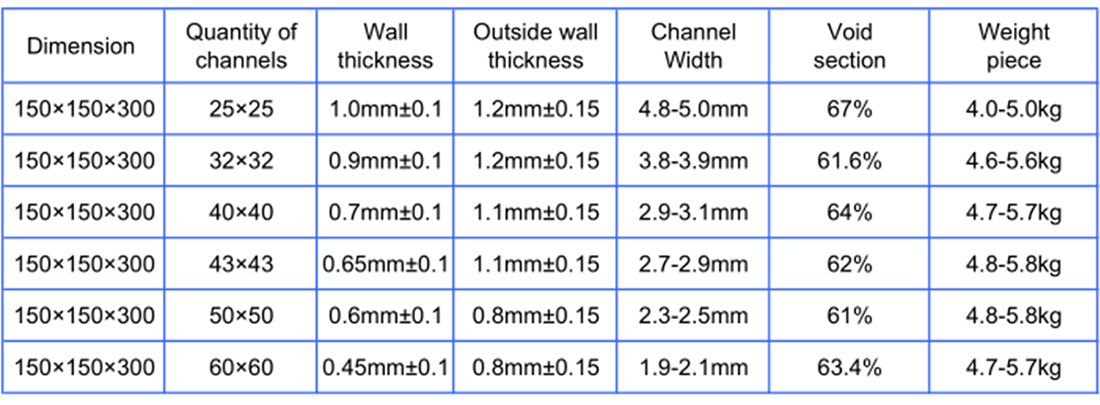

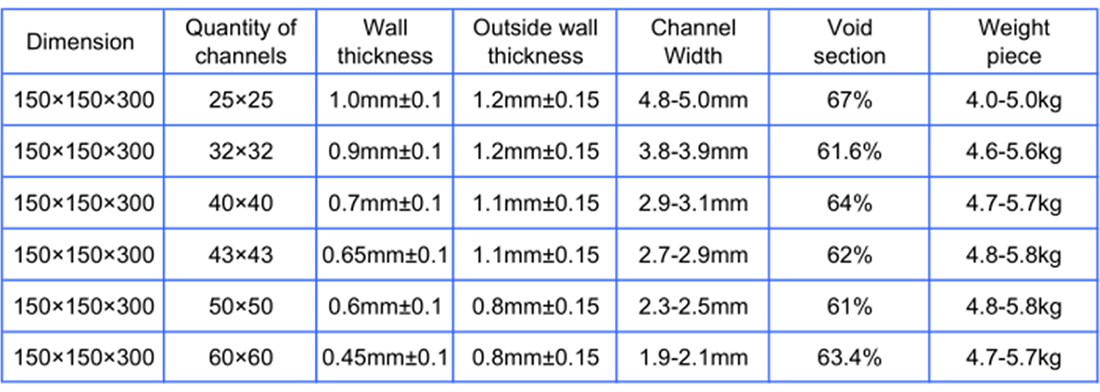

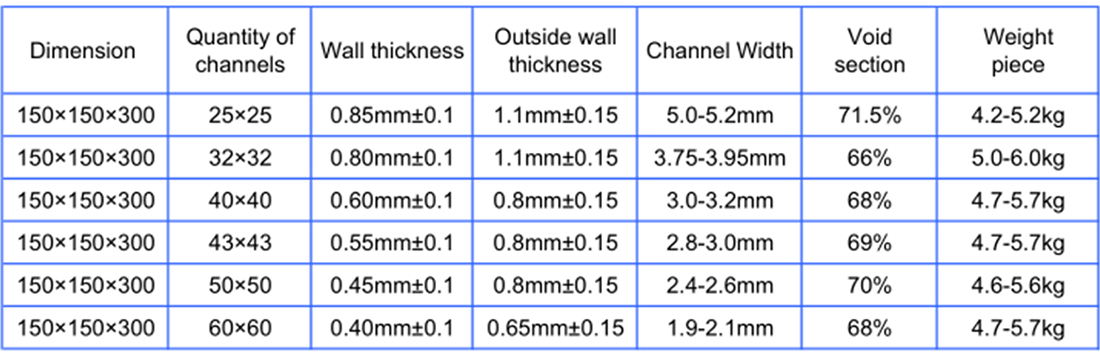

Dimentsion and other physical properties

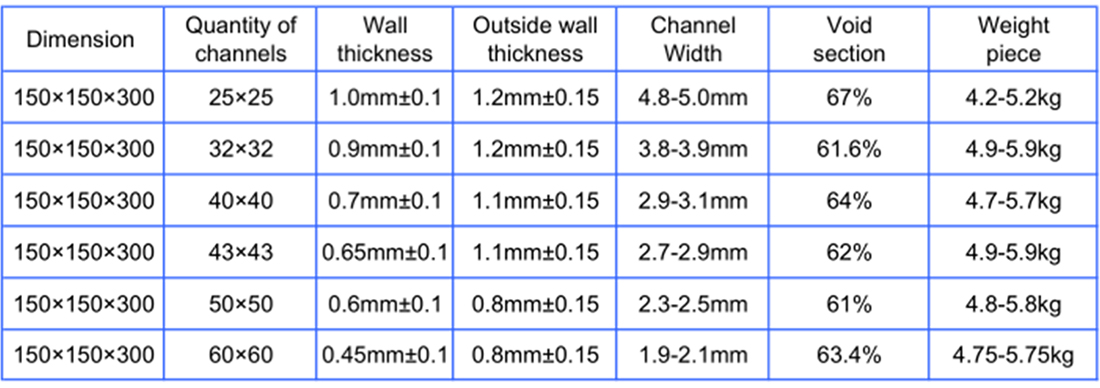

02. 刚玉莫来石

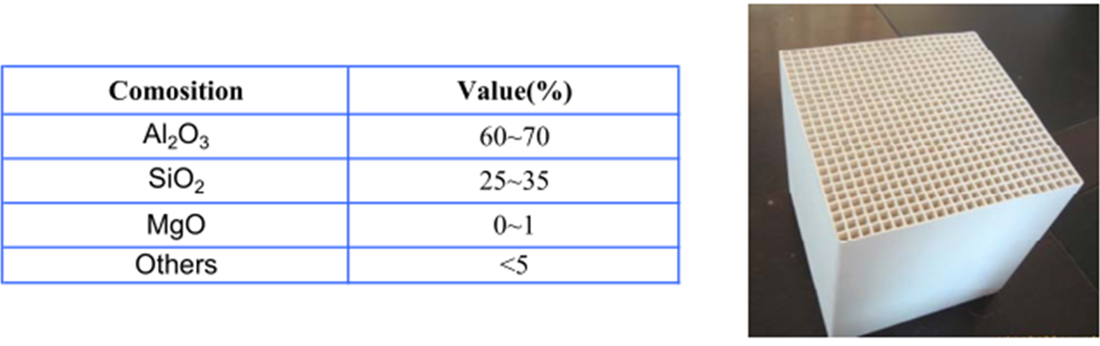

Chemical analysis

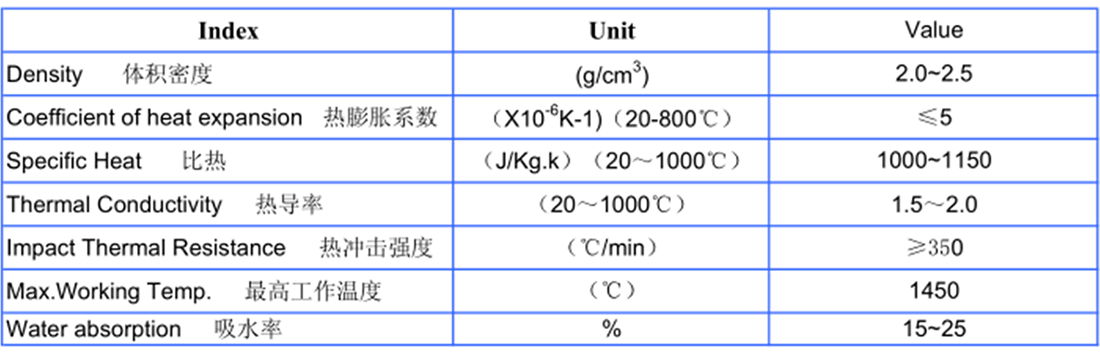

Physical properties

Dimentsion and other physical properties

03. 高铝

Chemical analysis

Physical properties

Dimentsion and other physical properties

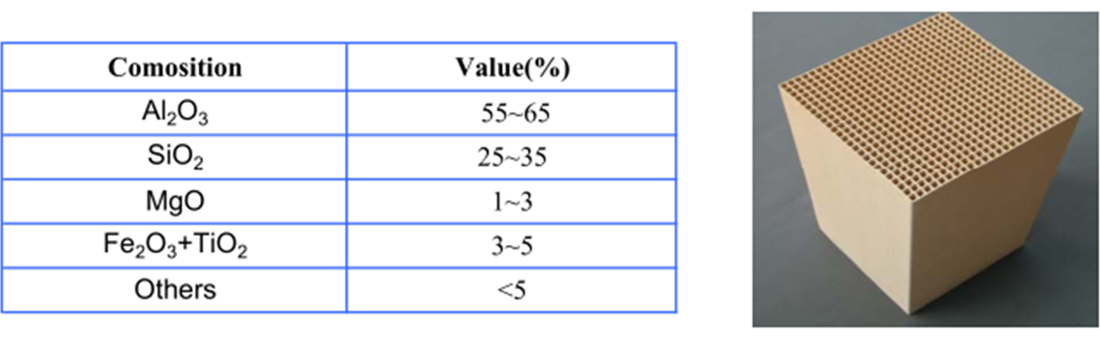

04. 莫来石

Chemical analysis

Physical properties

Dimentsion and other physical properties

05. 致密高铝

Chemical analysis

Physical properties

Dimentsion and other physical properties

06. 致密堇青石

Chemical analysis

Physical properties

Dimentsion and other physical properties